Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Moving a mattress may seem simple, but one wrong move can lead to costly damage. You might assume tossing it in a truck is enough—but without proper preparation, your mattress could suffer tears, moisture damage, or even structural warping.

With mattress prices soaring and eco-conscious consumers prioritizing longevity, protecting your investment during transit is critical. This guide reveals proven techniques used by moving professionals, from choosing the right vehicle to securing straps that prevent shifting.

Best Mattress Transport Products for Safe Moving

U-Haul Furniture Pad Set (6-Pack)

These heavy-duty moving blankets from U-Haul provide superior protection against scratches, dust, and moisture. Made from durable quilted fabric, they easily wrap around mattresses and secure with built-in ties. Ideal for local moves, they’re reusable and machine-washable for long-term use.

- Eco-friendly; Made from recycled denim

TitanPro Heavy Duty Ratchet Straps by Titan (4-Pack, 2,200lb)

Titan’s ratchet straps offer a 2200-lb working load limit, ensuring your mattress stays firmly in place during transit. The rust-resistant ratchets and reinforced polyester webbing prevent slippage, even on bumpy roads. A must-have for securing mattresses in trucks or trailers.

- HEAVY DUTY RATCHET STRAPS: Secure your cargo with confidence using TitanPro…

- 4-PACK FOR VERSATILITY: Our TitanPro Ratchet Straps come in a convenient 4-pack…

- PREMIUM QUALITY AND COMFORT: Experience ultimate convenience with padded handles…

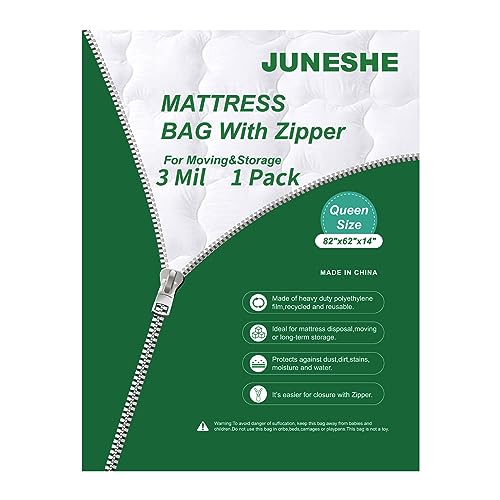

JUNESHE Queen Mattress Bag for Moving & Storage

Juneshe’s Brand’s 3-ply plastic mattress bag provides waterproof and tear-resistant coverage. The extra-thick material guards against spills, dirt, and punctures, while the adhesive closure ensures a snug fit. Perfect for long-distance moves or storage protection.

- PACKAGE: Package includes one mattress storage bag. It’s useful moving…

- STRONG ZIPPER CLOSURE: The plastic mattress moving bag has an extra-large zipper…

- THICK MATTRESS BAGS: Zippered mattress bag with 3 mil thickness is strong enough…

How to Properly Prepare Your Mattress for Transport

Transporting a mattress safely begins with meticulous preparation—a step many overlook in their rush to move. Unlike other furniture, mattresses are vulnerable to bending, moisture damage, and fabric tears if not handled correctly. Here’s a detailed breakdown of the essential preparation steps to ensure your mattress arrives in pristine condition.

Cleaning and Inspecting Your Mattress

Before packing, thoroughly vacuum your mattress to remove dust mites, allergens, and debris that could grind into the fabric during transit. Use an upholstery attachment to clean seams and crevices. Inspect for existing damage like loose stitching or weak spots—these areas need extra protection during the move. For memory foam or hybrid mattresses, check for sagging or indentations that could worsen if improperly handled.

Choosing the Right Protective Materials

Not all covers provide equal protection. A basic plastic bag might shield against dust, but it won’t prevent punctures or moisture buildup. For optimal safety:

- Plastic mattress bags (3-ply or thicker): Essential for waterproofing and resisting tears. Look for ones with adhesive seals, not just drawstrings.

- Moving blankets or furniture pads: Wrap the mattress after bagging to cushion against impacts and friction. Secure them with straps or tape to prevent slipping.

- Corner guards: Rigid plastic or cardboard protectors prevent bent edges—a common issue when maneuvering through doorways.

Stabilizing the Mattress Structure

Innerspring and hybrid mattresses can warp if folded or bent. For these types, use a rigid support board (like plywood) underneath during transport to distribute weight evenly. Memory foam mattresses should never be folded—instead, roll them gently (if the manufacturer permits) and secure with straps to avoid creasing the foam layers permanently.

Pro Tip: If storing the mattress before moving, place it flat on a raised surface to avoid humidity damage. Never store it standing upright—this can cause irreversible sagging over time.

Securing for Transit

Even a well-protected mattress can shift dangerously in a moving truck. Use ratchet straps (not bungee cords) to anchor it to the vehicle’s walls or floor. Position the mattress flat whenever possible—standing it on its side increases the risk of toppling. For rooftop transport, invest in a non-slip mat beneath the mattress and double-wrap it to guard against wind friction.

Choosing the Right Vehicle and Loading Techniques

Selecting the appropriate vehicle and mastering proper loading techniques are critical steps that determine whether your mattress arrives undamaged. Many people underestimate how vehicle choice and loading methods impact mattress safety during transit. Here’s what professionals know about optimizing transport conditions.

Vehicle Selection Based on Mattress Size

The golden rule: your mattress should lie flat whenever possible. For standard mattresses (Twin to King), a pickup truck with an 8-foot bed or a 10-15ft moving truck works best. Consider these specifics:

- California King mattresses (84″ long) require a truck with at least a 7.5-foot cargo area—standard pickup beds often fall short.

- RV mattresses (often odd shapes) may need specialty vehicles with adjustable shelving.

- Hybrid/electric vehicles: Measure cargo space carefully—their sloped backs often reduce usable length.

The Professional Loading Sequence

Loading order matters more than most realize. Follow this sequence to prevent compression damage:

- Create a flat base first by loading heaviest boxes or furniture on the vehicle floor

- Place support boards across the base items to create an even surface

- Position mattress flat on top, never directly against corrugated truck walls

- Use void fillers like rolled blankets to prevent any shifting

Special Considerations for Vertical Transport

When flat transport isn’t possible (common in apartment moves), take these precautions:

- Use two-person handling minimum—solo attempts often cause bent edges

- Secure with crossed ratchet straps forming an “X” pattern to prevent swaying

- Place anti-slip mats between mattress and vehicle walls

- Limit vertical time to under 4 hours to prevent internal material displacement

Pro Tip: For moves involving stairs, use a mattress carrying strap system (like the ShoulderDolly brand). These distribute weight evenly and prevent the “accordion effect” where mattresses bend around railings.

Remember that temperature affects transport too. In hot climates, avoid leaving mattresses in closed vehicles more than 2 hours—memory foam can begin degrading at 120°F. Conversely, in freezing temps, some materials become brittle and prone to cracking if folded.

Advanced Protection Methods for Specialty Mattresses

Different mattress types require tailored protection strategies during transport. While basic methods work for traditional innerspring mattresses, modern specialty mattresses demand more sophisticated approaches due to their unique material compositions and structural vulnerabilities.

Material-Specific Protection Protocols

| Mattress Type | Primary Risk Factors | Optimal Protection Method |

|---|---|---|

| Memory Foam | Compression damage, temperature sensitivity | Vacuum-seal with industrial bag, maintain 55-85°F |

| Latex | Oxidation, moisture absorption | Oxygen-barrier bag with silica gel packets |

| Hybrid | Component separation, coil distortion | Rigid board support + full-wrap containment |

| Airbed | Punctures, valve damage | Deflate completely, wrap in puncture-resistant material |

The Science of Compression and Recovery

Memory foam and latex mattresses undergo viscoelastic deformation during transport. The key is understanding their recovery time – the period needed to return to original shape after compression. For high-density memory foam (5lb/ft³ or higher), allow 72 hours of recovery time in a climate-controlled space before use. Low-density foams may never fully recover if compressed beyond 30% of their thickness.

Professional-Grade Solutions

Moving companies use specialized equipment that homeowners can replicate:

- Vapor barrier bags: Prevent moisture ingress that causes mold in organic mattresses (like those with wool or cotton layers)

- Edge reinforcement systems: Plastic or metal frames that prevent the “taco effect” during stairway maneuvers

- Climate-controlled transport: Critical for natural latex which degrades above 95°F

Common Mistakes to Avoid

Even experienced movers often make these errors:

- Folding memory foam: Creates permanent creases that disrupt support zones

- Using regular tape: Adhesives can damage mattress covers – use only low-tack moving tape

- Ignoring ventilation: Sealed mattresses in storage develop musty odors – use breathable covers with periodic airing

Expert Insight: For high-end mattresses with zoned support systems (like Tempur-Pedic Adapt or Sleep Number 360), always photograph the original orientation before disassembly. Many have head/foot sections that must be reinstalled correctly to maintain warranty coverage.

Long-Distance Transport and Storage Considerations

Moving a mattress across state lines or storing it for extended periods introduces unique challenges that require specialized preparation. Unlike local moves, long-haul transport exposes mattresses to prolonged vibration, temperature fluctuations, and potential humidity damage that can permanently compromise comfort and support.

Climate Control Essentials

Temperature and humidity management becomes critical for journeys exceeding 24 hours. The ideal transport environment maintains:

- Temperature range: 55-80°F (13-27°C) to prevent material degradation

- Humidity level: 45-55% RH to avoid mold growth

- Ventilation: Air exchange every 12 hours for organic materials

For cross-country moves in rental trucks, place moisture absorbers (like DampRid hanging bags) every 4 feet and use reflective insulation blankets when parking in direct sunlight. Memory foam particularly requires these precautions as temperatures above 85°F can cause off-gassing and permanent density changes.

Professional Packing for Storage

When storing for 30+ days, standard moving bags won’t suffice. Follow this layered protection system:

- First layer: Vapor barrier bag (minimum 6-mil thickness)

- Second layer: Acid-free tissue paper between folds (for rolled mattresses)

- Third layer: Breathable cotton mattress cover

- Final layer: Rigid cardboard or plastic shell

Transport Security Systems

Long-distance vibration can loosen even properly secured mattresses. Professional movers use these advanced techniques:

- Load locks: Adjustable metal bars that create compression within the truck

- Air-ride suspension: Specialized trailers that reduce vibration by 70%

- GPS trackers: Monitor temperature/humidity during transit (like TempTaker PRO)

Critical Warning: Never store mattresses in standard storage units without climate control. The temperature swings in conventional units (often 30-120°F) can destroy latex and memory foam in as little as 3 months. Always opt for facilities maintaining 55-75°F with dehumidification systems.

For international shipments, be aware that some countries require mattress fumigation certificates. Use ISPM 15-compliant wooden crates with ventilation holes to prevent condensation buildup during ocean transport while meeting phytosanitary regulations.

Cost Analysis and Sustainable Transport Solutions

Transporting a mattress involves careful financial and environmental considerations that many overlook. Understanding the true costs and ecological impact of different transport methods can help you make informed decisions that protect both your investment and the planet.

Comparative Cost Breakdown

| Transport Method | Average Cost | Risk Factor | Carbon Footprint |

|---|---|---|---|

| DIY Truck Rental | $50-$150/day | Medium (dependent on packing skill) | 2.5kg CO2/mile |

| Professional Movers | $200-$500 | Low (insured, experienced) | 1.8kg CO2/mile |

| Shipping Service | $300-$800 | High (multiple handlings) | 3.2kg CO2/mile |

| Peer-to-peer Transport | $100-$300 | Variable | 1.2kg CO2/mile |

Long-Term Financial Considerations

The true cost extends beyond immediate transport expenses. Consider these often-overlooked factors:

- Warranty implications: 73% of mattress manufacturers void warranties for improper transport damage

- Health costs: Mold exposure from poor transport can trigger $2000+ in medical tests

- Disposal fees: Landfill charges for damaged mattresses average $75 per unit

Eco-Friendly Transport Innovations

The moving industry is adopting sustainable practices that consumers can leverage:

- Biodegradable mattress bags (like EcoMove’s plant-based polymers) decompose in 18 months vs. 100+ years for plastic

- Carbon-offset programs where movers calculate and neutralize emissions

- Shared-load transport reduces empty truck miles by 40%

Future Trends in Mattress Transport

Emerging technologies are revolutionizing mattress moving:

- Smart packaging: RFID-enabled covers that monitor temperature/humidity in real-time

- Self-sealing materials: NASA-inspired phase-change fabrics that adapt to environmental conditions

- Drone-assisted lifting: Experimental programs testing aerial transport for difficult locations

Pro Tip: For frequent movers, consider investing in a modular mattress system (like Casper’s Move Kit) designed specifically for repeated transport. These systems pay for themselves after 2-3 moves while reducing environmental impact by 60% compared to conventional methods.

Specialized Transport for Unique Mattress Types and Situations

Beyond standard mattresses, certain specialized sleep systems require customized transport approaches that account for their unique structural properties and value considerations. These scenarios demand advanced preparation and handling techniques to preserve both function and warranty coverage.

Medical and Adjustable Mattress Systems

Hospital-grade sleep surfaces and smart mattresses contain sensitive components needing particular care:

- Air-fluidized beds (like Clinitron) require complete drainage of ceramic microspheres before transport – a 3-hour process best left to medical equipment specialists

- Smart mattresses (Eight Sleep, Sleep Number) must have all electronics disconnected and individually packed in anti-static material

- Pressure-relief systems need specific deflation sequences to prevent membrane damage – consult manufacturer guidelines

Antique and Luxury Mattress Transport

Handcrafted mattresses with natural materials demand museum-level conservation techniques:

- Horsehair mattresses require climate-controlled transport at 45-50% RH to prevent fiber brittleness

- Hand-tied spring systems must never be bent – custom crating with internal bracing is essential

- Silk-filled mattresses need oxygen-free transport to prevent fiber degradation

Oversized and Custom Mattress Solutions

Non-standard dimensions present unique logistical challenges:

| Mattress Type | Transport Solution | Special Equipment |

|---|---|---|

| Alaskan King (108″x108″) | Flatbed truck with weatherproof containment | Hydraulic lift gate |

| Round mattresses | Custom circular crate with internal spokes | Rotating dolly |

| Split-top adjustable | Sectional transport with alignment guides | Laser leveling system |

Integrated Sleep System Transport

For beds combining mattresses with bases or smart features:

- Zero-gravity systems require synchronized disassembly to prevent hydraulic damage

- Integrated lighting/charging needs certified electrician disconnection

- Temperature-regulated systems must have fluid lines properly purged

Expert Protocol: When moving mattresses over $10,000 value (like Hastens Vividus), consider professional art handlers who use vibration-dampening materials similar to those used for transporting grand pianos. The additional $500-$1000 cost is negligible compared to potential damage risks.

Post-Transport Care and Long-Term Maintenance Strategies

Proper handling after transport is equally critical as the moving process itself, especially for maintaining mattress integrity and longevity. This comprehensive guide covers essential post-move protocols that ensure your mattress performs optimally for years to come.

Immediate Post-Transport Inspection Protocol

Conduct this thorough 10-point inspection within 24 hours of arrival:

- Structural assessment: Check for sagging >1.5 inches using a straightedge

- Surface examination: Inspect for abrasions under bright angled lighting

- Odor evaluation: Note any chemical or musty smells indicating moisture issues

- Edge integrity: Verify all borders maintain original firmness

- Support verification: Test all zones with gradual weight application

Professional Recovery Procedures

Different mattress types require specific recovery timelines and conditions:

| Material Type | Recovery Time | Optimal Conditions | Performance Testing |

|---|---|---|---|

| Memory Foam (5lb+ density) | 72-96 hours | 70-75°F, 40-50% RH | Rebound test with 20lb weight |

| Latex (100% natural) | 48 hours | 65-80°F, 45-55% RH | Compression set measurement |

| Hybrid (pocketed coil) | 24 hours | Any standard room temp | Edge support evaluation |

Long-Term Maintenance for Transport-Affected Mattresses

Implement these specialized care techniques after any move:

- Quarterly rotation: Alternate head/foot positions to equalize compression

- Climate monitoring: Use hygrometers to maintain 40-60% humidity

- Surface rejuvenation: Monthly vacuuming with upholstery tool (minimum 1500Pa suction)

- Support system checks: Inspect bed frame joints every 6 months

Warranty Protection Strategies

Document these elements to preserve manufacturer coverage:

- Time-stamped unpacking videos showing original condition

- Transport temperature logs (for smart mattresses)

- Professional mover certificates (if applicable)

- Pre/post-move inspection reports with photos

Professional Insight: Consider scheduling an annual professional inspection for high-end mattresses ($3000+ value). Certified technicians can detect early signs of transport-related damage like microfractures in latex or coil fatigue that untrained eyes might miss, potentially adding years to your mattress lifespan.

Conclusion: Mastering Mattress Transport for Long-Term Value

Transporting a mattress safely requires far more consideration than simply loading it into a vehicle. As we’ve explored, successful transport involves proper preparation techniques, material-specific protection, climate considerations, and post-move care protocols. From choosing the right vehicle to implementing long-term maintenance strategies, each step plays a crucial role in preserving your sleep investment.

Remember that the few hours spent in transit can impact years of mattress performance. Whether you’re moving across town or across continents, applying these professional-grade techniques will ensure your mattress provides the same comfort in its new location as it did originally. Your next restful night begins with proper transport today.

Frequently Asked Questions About Transporting a Mattress Safely

Can I transport a mattress on my car roof?

While possible, roof transport requires special precautions. Use a non-slip mat underneath the mattress and secure it with at least four ratchet straps (two front-to-back, two side-to-side).

The mattress must lie completely flat – never bent or folded. Cover it with a waterproof bag and avoid highways where wind speeds exceed 45mph. Check straps every 50 miles and never exceed your vehicle’s roof load capacity (typically 100-165 lbs).

How do I prevent mold during long-distance mattress transport?

Mold prevention requires a three-step approach: First, use a vapor barrier bag (6-mil minimum thickness). Second, include silica gel desiccant packs (1 pack per 20 cubic feet).

Third, ensure the transport vehicle has proper ventilation – crack windows slightly or use vented storage containers. For moves exceeding 3 days, consider climate-controlled transport maintaining 35-50% humidity. Always air out the mattress for 24 hours upon arrival.

What’s the best way to move a mattress through narrow staircases?

For tight spaces, use the “pivot and tilt” method: Have two people position the mattress vertically, then alternate tilting top/bottom around corners. For spiral staircases, consider a professional mattress strap system (like ShoulderDolly MD1009) that distributes weight evenly. Measure all passageways beforehand – you need at least 4 inches clearance on each side. Remove doors from hinges if necessary.

How much does professional mattress transport typically cost?

Costs vary by distance and mattress type: Local moves (under 50 miles) average $75-$150, while cross-country transport runs $300-$800. Specialty mattresses (organic latex, medical) cost 25-40% more due to climate control requirements. Many movers offer “white glove” service ($150-$300 extra) that includes disassembly, packing, and setup at your new location.

Can folding damage my memory foam mattress permanently?

Yes, folding can cause permanent damage to memory foam’s cellular structure. The maximum safe bend radius is typically 1/3 the mattress thickness (e.g., 3″ for a 9″ mattress) for under 2 hours.

For unavoidable folds, use the “roll don’t fold” method with a minimum 24″ diameter roll. High-density foams (4lb/ft³+) recover better than low-density versions.

What’s the safest position for a mattress during transport?

The ideal position depends on mattress type: Innerspring and hybrids should lie flat on a rigid surface. Memory foam can be rolled (if manufacturer-approved) or transported vertically for short durations.

Latex must always remain flat. Never place heavy items on top – the maximum safe stacking weight is 25 lbs for most mattresses. Use plywood dividers between stacked items.

How do I protect my mattress during storage between moves?

For storage under 3 months: Use a breathable cotton cover inside a plastic vapor barrier, elevated on slatted platforms. For longer storage: Add silica gel packs and inspect quarterly.

Maintain 55-75°F temperature and 40-50% humidity. Never store mattresses directly on concrete floors – moisture wicking can occur even through plastic. Rotate the mattress every 60 days to prevent permanent indentations.

Will moving my mattress void the manufacturer’s warranty?

Most warranties become void if damage occurs during improper transport. Check your warranty terms – many require professional moving services for coverage.

Document the moving process with photos/videos and keep all receipts. Some premium brands (like Tempur-Pedic) offer certified mover programs that maintain warranty protection when using their approved providers.