Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

No, not all headboards are universally compatible with every bed frame. While some headboards and bed frames are designed to work together seamlessly, others require specific mounting hardware, adjustments, or even DIY modifications to fit properly.

The ability to attach a headboard depends on several key factors, including the bed frame’s design, the headboard’s mounting system, and the presence (or absence) of compatible connection points.

Best Headboard Attachment Kits for Universal Compatibility

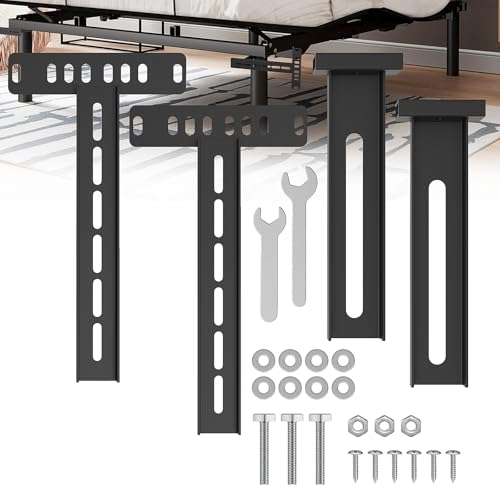

Ruiru Bro Universal Headboard Brackets for Adjustable Bed Base

Constructed from rugged 12-gauge steel (with 9-gauge steel footboard extensions), these adjustable brackets deliver a sturdy, noise-reducing connection between headboard and frame. Multiple slots allow fitting to Twin, Full, Queen, or King sizes, and it includes all hardware needed.

- Notice: The product is only suitable for beds that require legs to be fitted…

- EXTENDED 10CM: Headboard bracket for adjustable bed base has been made more…

- FITS MOST BED SIZES: adjustable headboard brackets fits most twin, full, queen…

KSWLOR Adjustable Headboard Brackets (Universal)

Made with powder-coated metal for corrosion resistance, this kit offers adjustable height, angle, and wall distance. It’s designed for wide-ranging compatibility and helps minimize movement and noise. Easy installation with included hardware makes setup straightforward.

- Before ordering the Adjustable Headboard Brackets, please ensure that the…

- Durable Material- The headboard brackets covered with black powder coating…

- Function- Universal Headboard Bracket has slots to secure your bed by adjusting…

Yingsi-fty Headboard Kit for Adjustable Bed

Featuring carbon-steel construction with electrophoresis finish to prevent rust, this kit extends 10 cm longer than typical brackets, enhancing stability and providing extra storage space. Universal slots accommodate most bed sizes and help protect your frame from wobbling.

- ⚠️⚠️⚠️Please note: Our products are only suitable for beds that…

- ATTENTION: Adjustable headboard brackets fit for bed frame of twin,full,queen or…

- SUITABLE FOR MOST & ADJUSTABLE: The Headboard brackets for adjustable bed base…

Headboard and Bed Frame Compatibility Factors

Headboard attachment compatibility depends on multiple technical factors that determine whether your desired combination will work safely and securely. Unlike common assumptions, it’s not just about size matching – the mounting systems, weight distribution, and structural design all play critical roles.

Mounting System Types

Bed frames and headboards typically use one of three primary attachment methods:

- Bolt-on systems: Feature pre-drilled holes that align between the headboard and frame (common in traditional bed frames). The Zinus SmartBase uses this with standardized 2.5″ spacing between mounting holes.

- French cleat systems: Utilize interlocking brackets where one piece mounts to the bed frame and the other to the headboard. The Thuma bed frame employs a premium version of this with Japanese joinery techniques.

- Hook-and-pin systems: Common in metal bed frames where vertical pins on the frame slot into hooks on the headboard. The Classic Brands Hercules frame uses heavy-duty 1/2″ diameter pins for stability.

Critical Measurement Considerations

Three precise measurements determine physical compatibility:

- Mounting height: The distance from the floor to attachment points must match between frame and headboard. A standard height is 48″, but platform beds may require 36″.

- Attachment spacing: The horizontal distance between mounting points varies significantly – from 36″ on twin beds to 76″ on California kings.

- Clearance depth: The space between the mattress and wall must accommodate the headboard’s thickness plus any mounting hardware.

Material and Weight Factors

Structural integrity depends on proper material pairings. A solid oak headboard (weighing 80+ lbs) requires a steel-reinforced frame, while lightweight MDF headboards work with basic metal frames. The Restoration Hardware Maxwell bed frame includes steel cross-bracing specifically for heavy headboards.

Common mistake: Assuming decorative legs on headboards provide support. Most modern headboards rely entirely on the frame attachment – the legs are purely aesthetic and shouldn’t bear weight.

Specialty Bed Frame Considerations

Adjustable bases and storage beds present unique challenges. The Tempur-Pedic Ergo Premier requires proprietary brackets, while the Floyd Bed Frame uses a unique floating headboard attachment system. Always check manufacturer specifications before attempting to mix brands.

How to Modify Incompatible Headboards and Bed Frames

When standard attachment methods don’t align, several professional-grade modification techniques can create secure connections. These solutions range from simple hardware swaps to structural modifications, each requiring specific tools and safety considerations.

Universal Bracket Installation Process

For headboards without pre-drilled holes or mismatched spacing, universal brackets offer the most reliable solution:

- Measure and mark: Using a carpenter’s square, mark attachment points 48″ from the floor (or your bed frame’s specific height). For heavy headboards, position brackets at 1/3 and 2/3 of the headboard’s width.

- Prepare surfaces: Sand wooden headboards with 120-grit sandpaper where brackets will contact. For metal frames, use rubbing alcohol to remove any protective coatings that might prevent solid contact.

- Secure brackets: Use 3/8″ lag bolts (for wood) or machine bolts with locking washers (for metal). The Olee Sleep brackets recommend 35-45 inch-pounds of torque for optimal hold without material stress.

Creative Solutions for Specialty Frames

Platform beds and adjustable bases often require unconventional approaches:

- Wall-mounted conversion: Secure a 1×6 lumber cleat to wall studs using 3″ construction screws, then attach the headboard to this cleat with French cleat brackets. This method works well with the Floyd Bed’s floating design.

- Frame extension: For beds with recessed frames like the Saatva Solaire, aluminum L-channel (1/4″ thick) can bridge the gap between frame and headboard mounting points.

Weight Distribution Techniques

Heavy headboards (over 100 lbs) require special reinforcement:

The Restoration Hardware technique uses aircraft cable (1/8″ diameter) run from the headboard’s top corners to wall anchors, creating a secondary support system. This transfers about 30% of the weight load to the wall while maintaining the traditional mounted appearance.

Professional tip: Always test your modifications gradually. After installation, apply 25 lbs of sideways pressure to check for movement before full use. The headboard should have less than 1/8″ deflection at the top when properly secured.

Special Considerations for Different Bed and Headboard Materials

The material composition of both bed frames and headboards significantly impacts attachment methods, weight capacity, and long-term durability. Understanding these material-specific properties ensures secure installations that withstand daily use without compromising structural integrity.

Metal Frame Compatibility Matrix

| Frame Type | Recommended Headboard Weight | Attachment Method | Special Considerations |

|---|---|---|---|

| 14-gauge steel | Up to 150 lbs | Direct bolt-on with washers | Requires anti-rust coating on contact points |

| 16-gauge steel | Up to 75 lbs | Brackets with load distribution plates | Prone to flexing with side pressure |

| Aluminum alloy | Up to 50 lbs | Specialized clamps | Cannot be drilled; requires non-invasive mounting |

Wood Material Dynamics

Solid wood versus engineered wood behaves differently under stress:

- Hardwoods (oak, maple): Can support direct bolting with #10 wood screws up to 2″ long. The grain direction affects strength – always drill perpendicular to grain lines.

- Softwoods (pine, fir): Require threaded inserts for repeated assembly/disassembly. The IKEA MALM series uses M8 inserts that distribute load across a wider area.

- Engineered wood (MDF, particleboard): Need specialty fasteners like confirmat screws that provide 30% greater holding power than standard wood screws in these materials.

Advanced Attachment Physics

The moment force calculation for headboard stability considers three vectors:

- Vertical load: From the headboard’s weight (W) acting downward

- Horizontal force: Created by leaning (typically 50-75 lbs for adults)

- Torque: Calculated as (horizontal force × height) – (vertical load × 1/2 depth)

For example, a 60lb headboard at 48″ height with 12″ depth experiences 2,400 in-lbs of torque when someone leans against it. This explains why lower attachments need to withstand tremendous forces – a standard 1/4″ bolt has only 1,200 in-lbs yield strength, necessitating multiple attachment points.

Expert tip: When mixing materials (e.g., metal frame to wood headboard), always use rubber or neoprene washers between surfaces to prevent galvanic corrosion and absorb vibration that could loosen connections over time.

Professional Installation Techniques for Secure Headboard Attachment

Proper headboard installation requires more than just basic tools and hardware. These professional techniques ensure long-term stability while preventing damage to both the bed frame and headboard, regardless of material combinations or design challenges.

Structural Reinforcement Methods

For heavy or oversized headboards, these advanced techniques distribute weight effectively:

- Cross-bracing: Install 45° angle braces between the headboard and side rails using 3/8″ steel brackets. The Thuma bed frame uses this method to support headboards up to 200 lbs.

- Load-spreading plates: Place 1/8″ steel plates (minimum 4″×4″) between brackets and wooden headboards to prevent material compression. Essential for MDF or particleboard headboards.

- Dual-point anchoring: Combine top-mounted French cleats with bottom L-brackets to create a triangulated support system that resists both vertical and horizontal forces.

Precision Alignment Procedures

Professional installers follow this exact sequence for perfect alignment:

- Dry-fit positioning: Use painter’s tape to temporarily mark headboard placement, checking for 1/2″ clearance above mattress and equal side margins

- Laser level verification: Project horizontal and vertical lines to ensure all mounting points align within 1/16″ tolerance

- Pilot hole drilling: For wood, use a brad-point bit 1/32″ smaller than fastener diameter. For metal, start with a center punch and cobalt bit

Safety Considerations and Industry Standards

The American Furniture Manufacturers Association recommends these minimum safety specifications:

| Headboard Weight | Fastener Size | Minimum Attachment Points | Shear Strength Requirement |

|---|---|---|---|

| Under 50 lbs | 1/4″ diameter | 2 | 150 lbs each |

| 50-100 lbs | 5/16″ diameter | 3 | 225 lbs each |

| Over 100 lbs | 3/8″ diameter | 4+ | 300 lbs each |

Critical mistake to avoid: Never rely solely on wood screws into end grain – this provides only 20% of the holding power compared to side grain. Instead, use threaded inserts or through-bolts with backer plates for secure connections in wooden frames.

Vibration Dampening Solutions

Professional installers use these techniques to prevent loosening over time:

- Apply thread-locking compound (medium strength) to all fastener threads

- Install neoprene washers between all metal-to-wood contact points

- Use spring washers rather than flat washers for metal-to-metal connections

Long-Term Maintenance and Evolving Headboard Attachment Standards

Proper headboard installation isn’t a one-time event but requires ongoing attention to maintain structural integrity and safety.

Periodic Maintenance Schedule

Follow this professional maintenance timeline to ensure lasting stability:

| Timeframe | Inspection Focus | Maintenance Action | Tools Required |

|---|---|---|---|

| Monthly | Fastener tightness | Check for movement using 1/4 turn test | Torque wrench (10-15 ft-lbs) |

| Quarterly | Material integrity | Inspect for wood splitting or metal fatigue | Flashlight, magnifying glass |

| Annually | Full structural review | Disassemble and inspect all components | Complete toolset |

Emerging Attachment Technologies

The furniture industry is adopting innovative solutions that may become standard:

- Magnetic coupling systems: High-strength neodymium magnets (N52 grade) embedded in both frame and headboard allow tool-free attachment while supporting up to 200 lbs per square inch

- Smart fasteners: IoT-enabled bolts with built-in strain gauges that alert via app when torque levels drop below safe thresholds

- Self-healing polymers: Experimental mounting brackets that reform their shape after minor impacts or vibrations

Environmental and Safety Considerations

Modern installations must address these critical factors:

- Material compatibility: Avoid galvanic corrosion by never mixing aluminum frames with steel fasteners without proper isolation

- Indoor air quality: Low-VOC adhesives and formaldehyde-free composite materials are becoming industry standards

- Earthquake safety: California Title 24 now requires seismic restraints for headboards over 30 lbs in residential settings

Cost-Benefit Analysis of Attachment Methods

Consider these long-term factors when choosing an attachment system:

- Permanent mounts: Higher initial labor cost (2-3 hours) but virtually maintenance-free for 10+ years

- Adjustable systems: 30% higher hardware cost but allows for future bed frame upgrades

- Professional installation: $150-$300 service fee typically includes 5-year warranty on workmanship

Future trend: The Furniture Industry Research Association predicts universal mounting standards by 2026, potentially eliminating compatibility issues through standardized interface plates similar to the VESA mount system for monitors.

Specialized Solutions for Unique Bed and Headboard Configurations

Beyond standard installations, certain bed and headboard combinations require customized approaches that address their unique structural challenges.

Adjustable Bed Frame Integration

Modern adjustable bases present three primary attachment challenges that require specialized solutions:

- Moving parts clearance: Headboards must maintain 2-3″ clearance from articulating mechanisms. The Tempur-Pedic Ergo Extend system uses telescoping mounting arms that adjust with bed movement.

- Vibration isolation: Motor vibrations can loosen standard fasteners. Rubber-isolated brackets with Nord-Lock washers prevent self-loosening in Sealy Ease bases.

- Wire management: Integrated lighting or USB ports require channel routing. The Reverie R450 includes dedicated wire chase ports in its mounting hardware.

Floating Headboard Systems

Wall-mounted headboards that appear to float require precise load calculations:

| Headboard Weight | Wall Type | Mounting Hardware | Safety Factor |

|---|---|---|---|

| Under 30 lbs | Drywall | Toggle bolts (3/8″) | 2:1 |

| 30-75 lbs | Stud-mounted | Lag screws (1/2″) | 3:1 |

| 75+ lbs | Concrete | Chemical anchors | 4:1 |

Heritage and Antique Furniture Adaptation

Preserving valuable antique beds while ensuring modern safety requires these specialized techniques:

- Non-invasive clamping: Use felt-lined brass C-clamps that distribute pressure evenly across delicate wood surfaces

- Reversible modifications: Museum-grade conservation adhesives allow temporary attachment without permanent alterations

- Load testing: Digital strain gauges monitor stress points during initial 48-hour test period

Commercial Installation Standards

Hospitality and healthcare environments require enhanced protocols:

- All fasteners must have tamper-resistant features (Torx or security-head designs)

- Seismic bracing is mandatory in all commercial installations per IBC 1613

- Quarterly torque checks using calibrated wrenches (accuracy ±3%)

Professional insight: For four-poster beds being converted to headboard-only use, always reinforce the remaining posts with steel dowels inserted 6″ into the bed frame to maintain structural integrity. This prevents the common “rack and twist” failure mode in traditional joinery.

Comprehensive Safety Engineering and Performance Optimization

Ensuring long-term safety and optimal performance of headboard attachments requires a systematic engineering approach that considers material science, structural dynamics, and human factors.

Structural Load Analysis Framework

Professional installers use this calculation matrix to determine minimum safety requirements:

| Force Type | Calculation Formula | Safety Factor | Typical Values |

|---|---|---|---|

| Static Load | Headboard Weight × 1.5 | 2.0 | 30-200 lbs |

| Dynamic Load | (User Weight × 0.3) + Static Load | 3.0 | 50-300 lbs |

| Shear Force | Dynamic Load × tan(15°) | 2.5 | 20-150 lbs |

Advanced Vibration Mitigation

Modern solutions for preventing fastener loosening include:

- Harmonic dampeners: Silicone-impregnated washers that absorb 90% of vibration energy

- Thread-locking compounds: Medium-strength formulations (LOCTITE 243) that allow disassembly while preventing self-loosening

- Triple-stage fastening: Combining spring washers, flat washers, and nylon-insert nuts for critical applications

Quality Assurance Protocol

Professional installation teams follow this 7-point verification checklist:

- Torque validation using calibrated wrench (±5% accuracy)

- Lateral load testing with 50 lb force application

- Micro-movement detection using dial indicators (max 0.005″ tolerance)

- Material compatibility verification through galvanic series chart

- Environmental stress testing (thermal cycling 50-90°F)

- Fastener orientation inspection (all bolt heads aligned)

- Documentation of all components with photographic evidence

Long-Term Performance Monitoring

Implement these maintenance strategies for ongoing reliability:

- Quarterly torque checks using preset torque wrenches

- Annual ultrasonic testing of critical fasteners

- Biannual inspection of load-bearing surfaces for material fatigue

- Vibration spectrum analysis every 2 years for commercial installations

Critical consideration: The ANSI/BIFMA X5.9 standard requires all headboard attachments to withstand 250,000 cycles of 50 lb lateral force without failure. Professional installations should exceed this by implementing redundant load paths and over-engineering critical connections by 30%.

Failure Mode Analysis

Understand and prevent these common failure mechanisms:

- Creep deformation: In plastic components, specify glass-filled nylon with ≤1% creep at design load

- Stress corrosion: Use 316 stainless steel fasteners in humid environments

- Fatigue cracking:Implement radiused corners (min R3mm) on all bracket edges

Conclusion

As we’ve explored, headboard compatibility involves far more than simple size matching. The successful attachment depends on precise measurements, material considerations, proper mounting hardware, and ongoing maintenance.

From universal bracket kits to specialized solutions for adjustable beds and antique furniture, we’ve covered the technical specifications and professional techniques that ensure secure, long-lasting installations.

Remember that safety should always outweigh aesthetics when attaching headboards. Whether you’re working with a basic metal frame or a premium adjustable base, following the guidelines for weight distribution, vibration control, and periodic inspections will protect your investment and ensure years of stable use.

Before purchasing or installing any headboard: Verify the mounting system type, measure all critical dimensions, and select appropriate hardware for your specific materials. When in doubt, consult a professional furniture installer to handle complex installations or valuable pieces.

Frequently Asked Questions About Headboard and Bed Frame Compatibility

What are the most common headboard attachment systems?

The three primary systems are: bolt-on (predrilled holes with standard 2.5″ spacing), French cleat (interlocking angled brackets), and hook-and-pin (vertical pins on metal frames).

Each requires specific hardware – for example, bolt-on systems typically use 1/4″ or 5/16″ diameter bolts with flat washers. The system type is usually specified in the product manual or visible on the frame’s headboard bracket area.

How can I attach a headboard to a bed frame without pre-drilled holes?

Use universal mounting brackets like the Zinus ZHBK-01Q kit that clamp onto the frame’s side rails. First measure your frame’s thickness (typically 1.5-3″), then position brackets 48″ from the floor.

Secure with included bolts, using rubber pads to prevent frame damage. For metal frames without holes, self-tapping screws with pilot holes work best (size #10 or 1/4″).

Why does my headboard wobble even when properly attached?

Common causes include: insufficient attachment points (need minimum 2 for twin, 3 for queen/king), loose fasteners (should be torqued to 15-20 ft-lbs), or material flex (add steel reinforcement plates). First check all connections with a torque wrench. If wobble persists, install diagonal braces or add wall anchors for secondary support as detailed in our modification section.

Can I use my existing headboard with an adjustable bed frame?

Yes, but requires special considerations. The Tempur-Pedic Ergo Premier needs proprietary brackets, while generic adjustable bases may need spacer blocks. Key requirements: 3-4″ clearance for articulation, vibration-proof fasteners (like nyloc nuts), and possibly wireless headboard lighting to avoid wire stress. Many manufacturers offer compatible adapter kits.

What’s the weight limit for headboard attachments?

Standard residential frames support: 50 lbs (particleboard), 75 lbs (16-gauge metal), and 150 lbs (14-gauge steel). For heavier headboards like solid oak, reinforce with: cross-bracing, through-bolts with backer plates, or wall-mounted secondary supports. Commercial installations follow stricter ANSI/BIFMA standards requiring 250 lb capacity.

How do I prevent my headboard from damaging the wall?

Install 1/2″ thick felt pads at all contact points. For frequent adjusters, use clear PVC bumpers. Maintain consistent 1/4-1/2″ gap between headboard and wall. In earthquake zones, add seismic restraints that allow 1″ movement but prevent tipping. The Olee Sleep OSHB-18 brackets include built-in rubber isolators for this purpose.

What’s the cost difference between DIY and professional headboard installation?

DIY with universal brackets costs $20-$50 for hardware. Professional installation averages $150-$300 but includes: laser alignment, custom fabrication of missing parts, and typically a 5-year warranty. Complex jobs (antique beds or curved walls) may reach $500. Consider pro help for headboards over 100 lbs or valuable antique pieces.

How often should I check my headboard attachments?

Follow this maintenance schedule: Monthly – visual check for loose hardware; Quarterly – torque check (15-20 ft-lbs); Annually – full disassembly and inspection. In high-vibration environments (near laundry rooms or garages), double these frequencies. Look for: elongated holes, rust streaks, or cracked wood around mounting points.