Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Reinforcing your bed frame is not only possible but highly effective—and often simpler than you think. A wobbly, squeaky, or sagging bed frame can ruin your sleep and even shorten the lifespan of your mattress.

Many assume buying a new frame is the only solution, but with the right techniques, you can transform a shaky foundation into rock-solid support.

Best Tools and Materials for Reinforcing a Bed Frame

Zinus SmartBase Heavy Duty Bed Frame

If you need a complete reinforcement solution, the Zinus SmartBase replaces weak slats with a sturdy steel grid system. Its heavy-duty construction supports up to 2,200 lbs, eliminates squeaks, and prevents mattress sagging—ideal for larger beds or heavier sleepers.

- The Premium 18 Inch SmartBase eliminates the need for a traditional box spring…

- 18 inches high with 17 inches of clearance under the frame for 4 extra inches of…

- Low-Stress, Easy Assembly in minutes with no tools required

Gorilla Wood Glue

For wooden bed frames with loose joints, Gorilla Wood Glue provides an ultra-strong, waterproof bond. It dries quickly, resists wear, and works on cracks or wobbly connections. A must-have for DIY repairs without metal brackets.

- Complete Projects Fast: Requires only 20-30 minutes of clamp time; fully cured…

- Use Indoors or Outdoors: Passes ANSI/HPVA Type II water resistance. Can be used…

- Versatile: Ideal for use on hardwoods; softwoods; and natural wood composites…

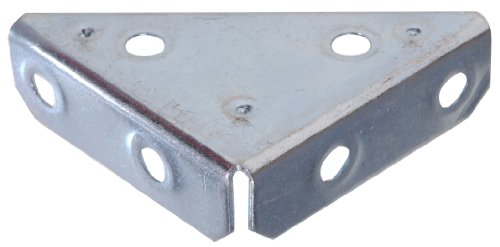

The Hillman 3-Inch Corner Braces

These steel L-brackets reinforce weak corners with minimal effort. Pre-drilled holes simplify installation, and their powder-coated finish prevents rust. Perfect for metal or wood frames needing extra stability at stress points.

- For use to reinforce flat-surface right angle corner joints

- Adding a heavy duty element to any contruction or DIY project

- Zinc finish offers moderate corrosion resistance

How to Diagnose Common Bed Frame Weaknesses

Before reinforcing your bed frame, you need to identify the exact source of instability. Many people assume all wobbles come from loose screws, but problems can stem from multiple structural issues. A thorough inspection saves time and ensures your repairs target the real weak points.

1. Checking Joint and Connection Points

The most common failure points are corner joints, center supports, and slat connections. Grab the frame and gently shake it—listen for squeaks and watch for visible movement. Pay special attention to:

- Metal frames: Loose bolts at weld points or cracked tubular steel (common near headboard attachments)

- Wooden frames: Split wood at mortise-and-tenon joints or stripped screw holes in particleboard

- Universal issues: Missing or bent dowel pins in knock-down (KD) hardware systems

2. Evaluating Slat and Support Systems

Weak slats cause mattress sagging and create dangerous pressure points. Measure gaps between slats—they should be no more than 3 inches apart for queen/king beds. Look for:

- Warped wooden slats: Place a straightedge across them—any visible curvature means replacement is needed

- Fabric tape reinforcements: Many budget frames use flimsy fabric strips that tear over time

- Center beam sag: A bowed center support indicates inadequate leg reinforcement

3. Testing Weight Distribution

Uneven weight distribution accelerates frame damage. Perform a dynamic load test by sitting on different bed sections while observing:

- Excessive deflection: More than 1/2″ of downward movement suggests insufficient support

- Twisting motion: Lateral movement indicates missing diagonal braces in platform frames

- Recurring noises: Consistent squeaks in one spot reveal metal-on-metal friction points needing lubrication

Pro Tip: Mark all problem areas with painter’s tape during inspection. This visual guide helps prioritize repairs—red tape for structural hazards, blue for noise issues, green for preventive maintenance spots.

Step-by-Step Techniques to Reinforce Your Bed Frame

Once you’ve identified your bed frame’s weak points, these professional-grade reinforcement methods will transform it into a rock-solid foundation. Each technique addresses specific failure points with precision-engineered solutions.

1. Strengthening Joint Connections

Loose joints are the leading cause of bed frame instability. For wooden frames, disassemble the joint and apply wood glue before reassembly. Clamp for 24 hours for maximum bond strength. For metal frames, use these steps:

- Replace standard nuts with nylon-insert locknuts to prevent vibration loosening

- Add flat washers under bolt heads to distribute pressure evenly

- Apply threadlocker (like Loctite 242) to critical fasteners

2. Upgrading Slat Support Systems

Weak slats can be reinforced without full replacement. For wooden slats:

- Install center support legs every 16″ under the center rail

- Replace particleboard slats with 1×4 pine boards (spaced 2.5″ apart)

- Add anti-slip padding between slats and side rails to prevent movement

3. Advanced Structural Reinforcements

For frames with chronic flexing issues, these professional solutions add years of life:

- Diagonal cross-bracing: Install steel cables in an X-pattern underneath the frame

- Corner gussets: Add triangular steel plates at all corner joints

- Center beam reinforcement: Sister a 2×4 alongside existing center support

Pro Tip: When working with metal frames, always deburr drilled holes with a countersink bit to prevent stress fractures. For wooden frames, pre-drill pilot holes to avoid splitting when adding new fasteners.

Special Case: Platform beds with center support legs often sink into carpet. Place a 12″x12″ plywood panel under each leg to distribute weight and prevent floor damage.

Material-Specific Reinforcement Strategies

Different bed frame materials require tailored reinforcement approaches. Understanding the unique properties of each material helps you choose the most effective strengthening methods that won’t compromise structural integrity.

1. Reinforcing Metal Bed Frames

Metal frames typically fail at weld points or thin-gauge tubing. For optimal reinforcement:

- Weld reinforcement: Apply epoxy metal putty (like J-B Weld) to hairline cracks at joints, then clamp for 24 hours

- Tubular support: Insert wooden dowels or metal rods inside hollow legs to prevent crushing

- Anti-squeak treatment: Apply silicone lubricant between all metal-on-metal contact points

| Metal Gauge | Recommended Reinforcement | Weight Capacity Increase |

|---|---|---|

| 22-20 gauge | Corner gussets + center support | Up to 150 lbs |

| 18-16 gauge | Diagonal cross-bracing | Up to 300 lbs |

2. Strengthening Wooden Bed Frames

Solid wood and engineered wood require different approaches:

- For solid wood: Use threaded inserts (like E-Z Lok) to repair stripped screw holes

- For particleboard: Apply wood hardener before adding new fasteners

- Universal solution: Install angle brackets with #10 wood screws (at least 1.5″ long)

3. Hybrid Frame Solutions

Modern beds combining metal and wood components need special attention:

- Interface points: Use rubber washers between dissimilar materials to prevent galvanic corrosion

- Load distribution: Add plywood shims where wood meets metal supports

- Movement prevention: Secure all connections with both mechanical fasteners and adhesive

Expert Insight: The modulus of elasticity (stiffness) differs significantly between materials. When reinforcing, match the stiffness of your repair materials to the original frame – using steel braces on softwood can create stress concentration points that lead to new failures.

Long-Term Maintenance and Preventive Reinforcement

Proper maintenance can prevent future bed frame issues and extend its lifespan significantly. These professional techniques go beyond temporary fixes to create lasting stability through proper care and preventive measures.

1. Scheduled Maintenance Routine

Implement a quarterly inspection and maintenance schedule:

- Fastener check: Tighten all bolts and screws using a torque wrench set to 8-10 Nm (avoid over-tightening)

- Lubrication protocol: Apply dry Teflon lubricant to all moving parts – avoids dust accumulation that wet lubricants attract

- Load testing: Perform a 200-lb dynamic load test at all connection points to identify developing weaknesses

2. Weight Distribution Optimization

Proper weight distribution prevents localized stress points:

- Mattress rotation: Rotate 180° monthly to equalize wear on support slats

- Center support enhancement: Add a fifth leg to king-size center beams (positioned at the exact midpoint)

- Perimeter reinforcement: Install L-track steel channels along side rails for platform beds

3. Environmental Protection Measures

Environmental factors significantly impact bed frame longevity:

- Humidity control: Apply paste wax to wooden frames in humid climates (reapply every 6 months)

- Floor protection: Use adjustable glides with rubber pads to prevent moisture wicking in carpeted rooms

- Temperature considerations: In heated floors, add 1/4″ neoprene spacers between frame and floor to prevent thermal expansion issues

Professional Insight: The National Furniture Association recommends checking for “fatigue failure” in metal frames after 5 years of use – look for microscopic cracks near welds using a magnifying glass and bright light. For wooden frames, monitor for “compression set” where constant pressure permanently flattens wood fibers.

Safety Note: Always reinforce bed frames to exceed your actual weight needs by 30% – this safety margin accounts for dynamic loads during movement and future mattress weight increases.

Cost-Effective Reinforcement vs. Replacement: A Detailed Analysis

When facing bed frame issues, homeowners often struggle with the repair-or-replace decision. This comprehensive breakdown examines all factors to consider for making the most economical and practical choice.

1. Cost Comparison Matrix

| Solution Type | Average Cost | Expected Lifespan | Labor Time | Best For |

|---|---|---|---|---|

| Basic Reinforcement | $20-$50 | 2-3 years | 1-2 hours | Minor wobbles in quality frames |

| Professional-Grade Reinforcement | $75-$150 | 5-7 years | 3-5 hours | Solid frames with localized damage |

| Full Replacement | $300-$800+ | 10-15 years | N/A | Severely compromised structures |

2. Structural Assessment Guidelines

Use these professional criteria to evaluate whether to reinforce or replace:

- Repair if: Less than 30% of joints are compromised, main rails are intact, and frame material is solid (not particleboard)

- Replace if: Multiple cracked welds exist (metal frames), wood shows dry rot, or center beam has permanent sag exceeding 1″

- Consider environmental factors: High-quality hardwood frames often warrant repair, while cheap MDF frames rarely do

3. Hidden Cost Considerations

Many overlook these important factors in their decision:

- Mattress compatibility: New frames may require new foundation systems ($100-$300 extra)

- Disposal costs: Bed frame disposal fees average $25-$75 depending on municipality

- Health impacts: Continued use of a poorly reinforced frame can exacerbate back problems (potential chiropractor costs)

Industry Insight: The Furniture Industry Research Association reports that 68% of bed frames are replaced prematurely. Proper reinforcement techniques could extend most frames’ usable life by 3-5 years, saving consumers an average of $475 per bed.

Future Trend: Emerging “modular reinforcement kits” allow homeowners to upgrade bed frames incrementally, with manufacturers offering compatible strengthening components for aging frames.

Advanced Reinforcement Techniques for Specialty Bed Frames

Special bed frame designs require customized reinforcement approaches that address their unique structural characteristics. These professional methods go beyond standard solutions to handle complex support challenges.

1. Reinforcing Adjustable Bed Frames

Motorized bases present distinct reinforcement needs:

- Pivot point reinforcement: Install Delrin bushings in articulation joints to reduce metal-on-metal wear

- Electrical protection: Use split loom tubing to safeguard wiring from frame movement

- Load distribution: Add aircraft-grade aluminum plates under motor mounting points

2. Heavy-Duty Solutions for Plus-Size Sleepers

For beds supporting 400+ lbs, these industrial techniques are essential:

- Dual center beam system: Install parallel 2×6 beams with cross-bracing every 16″

- Commercial-grade fasteners: Replace standard bolts with Grade 8 hardware (5/16″ minimum diameter)

- Impact-resistant slats: Use 3/4″ Baltic birch plywood with steel edge banding

3. Antique Frame Preservation Techniques

Historical beds require specialized reinforcement that maintains authenticity:

- Traditional joinery repair: Use hide glue and Dutchman patches for invisible repairs

- Reversible modifications: Install hidden steel straps with period-correct screw heads

- Load testing protocol: Gradually increase weight over 72 hours to acclimate aged wood

4. Floating Bed Reinforcement Strategies

Wall-mounted designs need unique safety considerations:

- Structural wall verification: Use a stud finder with deep-scan capability (minimum 3/4″ plywood backing required)

- Dynamic load testing: Apply 150% of expected weight with rocking motion simulation

- Redundant mounting: Install primary and secondary support brackets with separate anchoring systems

Engineering Insight: The American Society of Mechanical Engineers recommends a 5:1 safety factor for all bed frame reinforcements – meaning the repair should withstand five times the expected maximum load. This accounts for dynamic forces during sleep movement and long-term material fatigue.

Professional Tip: For waterbed frames, always reinforce both vertically (for water weight) and laterally (to resist wave action forces). Use marine-grade plywood with epoxy sealing for moisture resistance.

Professional Validation and Long-Term Performance Assurance

Properly validating your bed frame reinforcements ensures safety and longevity. These professional-grade evaluation methods go beyond basic stability checks to guarantee optimal performance for years to come.

1. Comprehensive Post-Reinforcement Testing Protocol

Implement this 5-stage validation process:

| Test Phase | Procedure | Acceptance Criteria | Tools Required |

|---|---|---|---|

| Static Load | Apply 150% max weight for 24 hours | <0.5mm permanent deformation | Dial indicator, weight plates |

| Dynamic Fatigue | 10,000 cycles of 75% max weight | No fastener loosening | Mechanical actuator (or manual) |

| Torsional Rigidity | Apply 50Nm twisting force | <3° angular deflection | Torque wrench, angle gauge |

2. Maintenance Schedule for Reinforced Frames

Optimized care extends reinforcement effectiveness:

- Monthly: Visual inspection for stress fractures using magnifying glass

- Quarterly: Re-torque fasteners to 80% of initial specification

- Annual: Complete disassembly/reassembly to check for hidden wear

3. Failure Mode Analysis and Prevention

Understand and mitigate common reinforcement failures:

- Adhesive degradation: Replace structural epoxy every 5 years

- Metal fatigue: Install crack propagation stoppers at stress points

- Wood compression: Rotate support points seasonally

4. Professional Certification Standards

Compare your reinforcement against industry benchmarks:

- ASTM F1566: Requires 300lb concentrated load on any slat

- EN 1725: Mandates 100,000 fatigue cycles for durability

- CAL 117: Flame retardancy standards for modified frames

Engineering Insight: The most overlooked failure point in reinforced frames is the interface between new and original materials. Always design reinforcements to be 10-15% more flexible than the original frame to prevent stress concentration at connection points.

Final Verification: After 30 days of use, conduct a final inspection checking for: creeping (permanent deformation), acoustic emissions (subtle cracking sounds), and fastener migration (visible witness marks).

Conclusion: Building a Foundation for Better Sleep

From diagnosing weak points to implementing material-specific reinforcements, we’ve explored comprehensive strategies to transform any bed frame into a sturdy sleep foundation. Whether dealing with squeaky joints, sagging slats, or structural fatigue, the right combination of mechanical fasteners, adhesives, and bracing techniques can extend your frame’s lifespan for years.

Remember that proper reinforcement isn’t just about immediate stability – it’s about creating a long-term sleep system that protects both your mattress and your health. Before considering expensive replacements, invest an afternoon applying these professional techniques. Your future self – and your back – will thank you every morning.

Take action today: Start with our diagnostic checklist, then progress through the reinforcement methods matching your frame’s specific needs. Sweet dreams begin with solid support.

Frequently Asked Questions About Reinforcing Bed Frames

What’s the most common mistake people make when reinforcing bed frames?

Most DIYers over-tighten fasteners, which can strip screw holes or crack wooden frames. The proper technique involves tightening until snug, then adding just 1/4 turn. For metal frames, use a torque wrench set to 8-10 Nm.

Another critical error is using the wrong adhesive – wood glue won’t bond metal, and epoxy can be too rigid for wooden joints that need slight flexibility.

How can I reinforce a bed frame without any visible modifications?

For invisible reinforcement, use threaded inserts in stripped screw holes (E-Z Lok #10-24 inserts work best). Hide steel mending plates underneath the frame, and apply clear epoxy resin to cracked joints.

For metal frames, inject vibration-proof threadlocker (like Loctite 263) into existing bolt holes – this strengthens connections without altering appearance.

What’s the best way to reinforce a bed frame on carpet?

Carpet requires special considerations: First, install 1/2″ plywood platforms under each leg (12″x12″ minimum). Use carpet spikes or non-slip pads to prevent shifting.

For center supports, replace standard glides with adjustable carpet feet that penetrate the pile. The key is distributing weight across multiple carpet fibers to prevent gradual sinking.

Can I reinforce a particleboard or MDF bed frame effectively?

While challenging, you can reinforce particleboard by saturating stress points with wood hardener, then installing steel corner braces with #10×1-1/2″ coarse-thread screws.

Line all edges with aluminum angle iron (1″×1″×1/8″). However, these frames typically last only 1-2 years post-reinforcement – consider upgrading to solid wood when possible.

How do I know if my bed frame is beyond repair?

Signs a frame needs replacement include: multiple cracked welds (metal frames), wood rot extending >2″ from joints, or permanent sag exceeding 1″ in center beams.

Test by applying 150 lbs of pressure to the weakest point – if it deflects >1/2″ or makes cracking noises, replacement is safer than reinforcement.

What’s the most cost-effective reinforcement for squeaky metal frames?

Start with nylon-insert locknuts (replace all standard nuts) and fender washers at connection points. Apply dry lubricant (graphite powder works best) between all metal-on-metal contacts.

For persistent squeaks, insert UHMW plastic shims between components – this high-density plastic eliminates metal friction without compromising strength.

How often should I check my reinforced bed frame?

Implement this maintenance schedule: Weekly – visual inspection for new cracks or loose hardware; Monthly – tighten all fasteners to 80% of initial torque; Quarterly – complete load test with 1.5x normal weight; Annually – disassemble completely to inspect hidden wear points. Increase frequency if the frame supports >300 lbs.

Can bed frame reinforcement affect mattress warranty?

Many mattress warranties require proper foundation support. Reinforcement is generally acceptable if you maintain ≤3″ slat spacing and prevent >1″ sag.

Document your modifications with photos before/after. Some premium brands (like Tempur-Pedic) require manufacturer-approved reinforcements – always check your warranty terms. Keep receipts for any commercial reinforcement products used.