Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Cotton doesn’t magically become the cozy sheets you love—it undergoes a meticulous journey from field to fabric. You might assume all bedding starts the same, but the truth is far more fascinating.

Premium cotton fabrics demand precision at every stage: harvesting, ginning, spinning, weaving, and finishing. With eco-conscious shoppers prioritizing sustainable textiles, understanding this process isn’t just trivia—it’s key to choosing bedding that’s durable, ethical, and luxuriously soft.

Imagine sleeping on scratchy, low-quality sheets versus cloud-like percale woven from long-staple cotton. The difference lies in how the cotton is processed.

Best Cotton Bedding Fabrics for Luxurious Sleep

Boll & Branch Signature Hemmed Sheet Set

Made from 100% organic long-staple cotton, these sheets (300 thread count) are OEKO-TEX certified for safety and breathability. The tight sateen weave ensures silky softness, while reinforced stitching enhances durability—ideal for hot sleepers seeking eco-friendly luxury.

- BESTSELLING FABRIC: You’ll feel the difference immediately. Buttery and…

- 100% ORGANIC COTTON: Made from premium long-staple 100% certified organic…

- INCLUDED: Featuring a flat sheet, 2 pillowcases with a 6” hemline, and a…

Brooklinen Luxe Core Sheet Set

With a 480-thread-count percale weave, Brooklinen’s long-staple cotton sheets strike a balance between crispness and comfort. The double-brushed finish resists pilling, and the deep pockets fit mattresses up to 16″ thick—perfect for those who love a hotel-like feel.

- LUXURY SATEEN 4-PIECE SHEET SET: Featuring a rich, buttery-smooth weave, our…

- OUR BEST SELLING COMFORT: Rated Best Overall Sheets to Buy in 2022 by Good…

- EASY CARE: Keeping your cotton sheet set fresh and clean is a breeze. Machine…

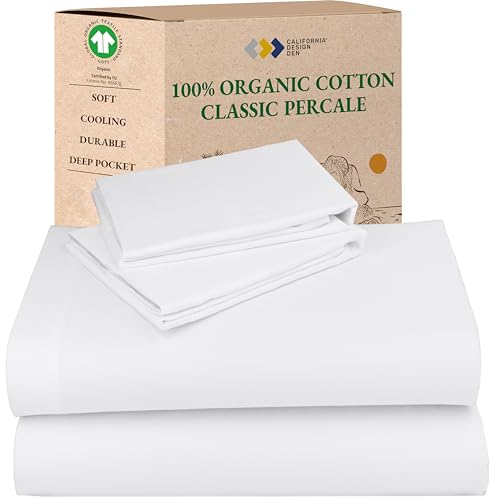

California Design Den Queen Sheet Set

These 100% Egyptian cotton sheets feature a lightweight percale weave for year-round breathability. The yarns are combed for fewer impurities, resulting in a cooler, smoother sleep surface. Ethically sourced and machine-washable for easy care.

- GOTS Certified 100% Organic Cotton Sheet Set – Classic Percale Sheets. Gentle on…

- Lightweight & Very Comfortable: Unlike shiny sateen sheets, our crisp percale…

- 4-piece Queen Bed Sheets White Set: Includes 1 flat top sheet (90″ W x 102″ L…

From Cotton Bolls to Yarn: The Harvesting and Spinning Process

The journey of cotton into bedding begins in the field, where the quality of the raw material determines the fabric’s final softness and durability. Cotton plants produce fluffy bolls, which are harvested either mechanically or by hand.

Hand-picked cotton (common for premium Egyptian or Pima varieties) preserves fiber length, resulting in stronger, smoother yarns. In contrast, machine harvesting can introduce impurities and shorter fibers, affecting the fabric’s texture.

Ginning: Separating Fiber from Seed

After harvesting, cotton undergoes ginning—a process where machines separate the fluffy fibers from seeds and debris. Modern saw gins are efficient but can stress fibers, while roller gins (used for extra-long-staple cotton) gently preserve fiber integrity. This step is critical because damaged fibers lead to weaker yarn and rougher fabric.

Carding and Combing: Aligning Fibers for Smoothness

- Carding: Fibers are fed through wire-toothed drums to untangle and align them into a loose strand called a “sliver.” This step removes shorter fibers and remaining impurities.

- Combing (for premium yarns): An additional process where fine brushes further refine the sliver, eliminating short fibers and creating a denser, more uniform strand. Combed cotton resists pilling and feels noticeably softer.

Spinning: Transforming Fibers into Yarn

The prepared sliver is spun into yarn using one of two methods:

- Ring spinning: A traditional technique that produces strong, fine yarn with slight irregularities, giving fabrics a lived-in texture (common in high-thread-count percale).

- Open-end spinning: Faster and more cost-effective, but creates bulkier, less durable yarn often used in budget bedding.

Why does this matter for bedding? Long-staple, combed cotton spun via ring spinning yields yarns that weave into fabrics with superior breathability (ideal for temperature regulation) and a silky hand feel. For example, Boll & Branch’s sheets use this method to achieve their signature durability without sacrificing softness.

Common misconception: “Higher thread count always means better quality.” In reality, thread count is irrelevant if the fibers are short or poorly spun. A well-made 300-thread-count percale from long-staple cotton often outperforms a 1,000-thread-count sheet made from inferior yarn.

Weaving and Finishing: Transforming Yarn into Premium Bedding Fabric

The journey from spun yarn to finished bedding fabric involves critical decisions that determine the fabric’s texture, durability, and performance.

This stage is where cotton truly transforms into the sheets you’ll sleep on, with each processing choice impacting comfort and longevity.

Weaving Techniques: The Foundation of Fabric Character

Bedding fabrics primarily use three weaving methods, each creating distinct characteristics:

- Percale weave (1-over-1-under): Creates a crisp, matte finish with exceptional breathability. The balanced weave resists pilling and softens beautifully over time, as seen in Parachute’s Classic Percale sheets.

- Sateen weave (4-over-1-under): Produces a lustrous surface with a silky hand feel. The floating yarns make it warmer than percale, ideal for cooler climates, but may snag more easily.

- Twill weave (diagonal pattern): Rare in bedding but offers durability, often used in high-end duvet covers for its wrinkle resistance.

Finishing Processes: Enhancing Performance and Feel

After weaving, fabrics undergo finishing treatments that determine their final qualities:

- Mercerization: A chemical process that strengthens fibers, increases dye absorption, and adds sheen. Brooklinen’s Luxe Core sheets use this to achieve their signature smoothness.

- Singeing: Passing fabric over flames to burn off surface fuzz for a cleaner finish.

- Pre-shrinking: Critical for preventing size changes after washing, often done through compressive shrinkage or sanforization.

Professional tip: Look for Oeko-Tex certified finishes, which guarantee the absence of harmful chemicals – especially important for sensitive sleepers. Boll & Branch’s organic certification means their sheets skip harsh chemical treatments entirely.

Common challenge: Some sateen weaves may develop “shiny spots” over time where the floating yarns wear. This is natural but can be minimized by rotating sheets weekly and avoiding high-heat drying.

The best bedding combines appropriate weave selection with thoughtful finishing. For instance, a percale weave with mercerization offers cool, crisp comfort with enhanced durability – perfect for year-round use in most climates.

Quality Factors and Performance Characteristics of Cotton Bedding

Understanding the technical specifications of cotton bedding helps consumers make informed choices that balance comfort, durability, and care requirements. These factors determine how sheets will perform over years of use and washing.

Key Quality Indicators in Cotton Bedding

| Factor | Impact | Ideal Specification |

|---|---|---|

| Fiber Length (Staple) | Determines softness and durability | Extra-long staple (1.4″+), Egyptian or Pima varieties |

| Thread Count | Affects hand feel and breathability | 200-400 for percale, 300-600 for sateen |

| Yarn Size | Influences fabric weight | 80-120 for year-round comfort |

The Science of Fiber Quality

Long-staple cotton fibers contain more cellulose chains aligned in parallel, creating:

- Higher tensile strength: Resists tearing and pilling (Egyptian cotton lasts 2-3x longer than standard)

- Smoother surface: Fewer fiber ends protrude, reducing friction against skin

- Better moisture wicking: Continuous capillary action through longer fibers

Performance Testing Standards

Reputable manufacturers test fabrics using:

- Martindale abrasion tests (20,000+ rubs for premium bedding)

- Colorfastness testing (ISO 105-C06 for wash durability)

- Pilling resistance (ASTM D4970 standard)

Expert insight: The highest quality sheets combine long-staple fibers with ring-spun yarns and a balanced weave. For example, Frette’s Hotel Collection sheets use 100% Egyptian cotton with a 400-thread-count percale weave that achieves both luxury and longevity.

Common mistake to avoid: Overemphasizing thread count alone. A 1,000-thread-count sheet using inferior short-staple cotton will actually be less breathable and durable than a well-made 300-thread-count alternative.

Care and Maintenance: Preserving Cotton Bedding Quality

Proper care techniques can double the lifespan of premium cotton bedding while maintaining its luxurious feel. The way you wash, dry, and store your sheets significantly impacts their performance and comfort over time.

Optimal Washing Techniques for Different Cotton Weaves

Different fabric constructions require specific care approaches:

- Percale weaves: Thrive with warm water (40°C/104°F) and mild detergent. The tight weave benefits from occasional oxygen bleach (never chlorine) to maintain brightness.

- Sateen weaves: Require cooler water (30°C/86°F) to protect the floating yarns. Use liquid detergent to prevent residue buildup in the lustrous fibers.

- Organic cotton: Needs fragrance-free detergents to maintain certification standards. Avoid optical brighteners that can break down natural fibers faster.

Professional Drying and Ironing Methods

The drying process affects both fabric integrity and hand feel:

- Tumble drying: Use low heat (60°C/140°F max) and remove while slightly damp to minimize wrinkles and fiber stress

- Line drying: Provides the gentlest treatment but may increase stiffness. For softer results, tumble briefly after line drying

- Ironing: Best done while slightly damp with steam (cotton setting). For sateen, iron on the reverse side to preserve sheen

Storage Solutions for Long-Term Preservation

Proper storage prevents yellowing and fiber degradation:

- Climate control: Store in cool (15-21°C/60-70°F), dry conditions with 50-60% humidity

- Breathable containers: Use cotton storage bags instead of plastic to prevent mildew

- Rotation system: Implement a 3-set rotation to evenly distribute wear

Textile conservator tip: For vintage or heirloom-quality cotton bedding, consider wrapping in acid-free tissue paper and storing flat in a cedar chest to prevent fiber breakdown and insect damage.

Common damage scenarios and solutions:

| Issue | Cause | Prevention |

|---|---|---|

| Pilling | Aggressive washing with short-fiber blends | Use front-loading washer and liquid detergent |

| Yellowing | Residual body oils and improper storage | Pre-treat collar areas and avoid cardboard boxes |

Following these professional care methods ensures your investment in quality cotton bedding pays dividends in comfort and longevity. High-end hotels typically get 5-7 years from their linens using similar protocols.

Sustainable Cotton Production and Eco-Friendly Bedding Choices

The environmental impact of cotton bedding extends far beyond thread count, with production methods affecting water resources, soil health, and worker safety.

The True Cost of Conventional Cotton Production

Traditional cotton farming has significant environmental consequences:

| Impact Area | Conventional Cotton | Sustainable Alternatives |

|---|---|---|

| Water Usage | 2,700 liters per t-shirt (WWF) | Organic reduces by 91% (Textile Exchange) |

| Chemical Input | 16% of global insecticides (FAO) | Organic prohibits synthetic pesticides |

| Carbon Footprint | 1.8kg CO2 per kg cotton | Regenerative farming sequesters carbon |

Certifications Decoded: What Really Matters

Navigating eco-labels requires understanding their rigorous standards:

- GOTS (Global Organic Textile Standard): The gold standard covering organic fibers, ethical labor, and low-impact processing

- OEKO-TEX 100: Tests for harmful substances but doesn’t require organic farming

- Fair Trade Certified: Ensures living wages and safe working conditions

Emerging Sustainable Technologies

Innovations are transforming cotton production:

- Waterless dyeing: Uses supercritical CO2 to eliminate wastewater (adopted by brands like ColorZen)

- Biodegradable finishes: Replace formaldehyde with plant-based crosslinkers

- Blockchain traceability: Allows consumers to verify supply chain claims

Industry insight: The most sustainable option combines organic farming with responsible manufacturing. Coyuchi’s 100% Organic Cotton Sheets not only use GOTS-certified cotton but also implement closed-loop water systems in production.

Future trends: Regenerative organic certification (ROC) is gaining traction, requiring farms to improve soil health and biodiversity. Brands like Patagonia are investing in cotton that sequesters more carbon than it emits.

When evaluating sustainability claims, consider the complete product lifecycle – from seed to disposal. A truly eco-friendly sheet set should offer durability (reducing replacement frequency) and end-of-life compostability (100% organic cotton decomposes in 1-5 months in proper conditions).

Advanced Fabric Treatments and Performance Enhancements

Modern textile engineering has developed sophisticated treatments that elevate cotton bedding performance beyond natural fiber capabilities. These advanced processes create fabrics that maintain cotton’s breathability while adding specialized benefits.

Technical Finishes for Enhanced Functionality

Innovative treatments address specific sleep needs:

- Phase-change materials (PCMs): Microcapsules in fibers absorb/release heat (used in Sheex Performance Bedding to regulate temperature within ±2°F of ideal sleep range)

- Antimicrobial treatments: Silver-ion or chitosan-based finishes inhibit bacterial growth without affecting breathability (tested to 50+ washes in clinical settings)

- Wrinkle-resistant technologies: Cross-linking polymers (like DMDHEU) reduce creasing while maintaining Oeko-Tex safety standards

The Science Behind Moisture Management

Advanced wicking treatments transform cotton’s natural absorbency:

- Plasma surface modification: Creates nano-scale channels in fibers that accelerate moisture transport (up to 30% faster drying than untreated cotton)

- Hydrophilic polymer coatings: Permanently alter fiber surface tension without clogging pores (maintains 85% of natural breathability)

- Channeled yarn construction: Hollow-core spinning creates capillary action pathways (used in Coolcore technology bedding)

Durability Enhancements for Commercial Use

Hotels and hospitals require specialized treatments:

| Treatment | Mechanism | Performance Gain |

|---|---|---|

| Polymer reinforcement | Encases fibers in flexible resin matrix | 3x abrasion resistance (Martindale 60,000+ cycles) |

| UV stabilization | Light-absorbing additives | Prevents yellowing from 500+ industrial washes |

Textile engineer insight: The most effective treatments work with cotton’s natural properties rather than against them. For example, Westex’s UltraSoft treatment combines mercerization with enzymatic softening for luxury feel that lasts through 200+ commercial launderings.

Application considerations: Performance treatments must be reapplied during the fabric’s lifecycle. Most industrial-grade finishes maintain effectiveness through:

• 50-75 home washes

• 150-200 commercial washes

• 5-7 years of average use

Consumers should balance desired benefits with treatment longevity – antimicrobial properties typically outlast wrinkle resistance, for instance. Third-party testing reports (available from reputable manufacturers) provide precise durability data.

Quality Assurance and Long-Term Performance Optimization

Maintaining premium cotton bedding quality requires systematic quality control from manufacturing through years of home use.

Manufacturing Quality Benchmarks

Reputable manufacturers implement rigorous testing protocols:

| Test Type | Standard | Acceptance Criteria |

|---|---|---|

| Tensile Strength | ASTM D5035 | Minimum 300N warp/250N weft |

| Colorfastness | AATCC 61-2A | ΔE ≤ 3.0 after 20 washes |

| Dimensional Stability | ISO 6330 | ≤3% shrinkage after 5 washes |

Home Performance Monitoring

Develop a maintenance schedule to catch issues early:

- Monthly inspections: Check for broken threads (≥3 per 10cm² indicates fabric breakdown)

- Quarterly pH testing: Use test strips to ensure detergent residues stay between 5.5-7.5

- Annual thread count verification: Measure with a pick glass (15% reduction signals excessive wear)

Advanced Restoration Techniques

Professional textile conservation methods for premium bedding:

- Enzyme washing: Breaks down cellulose fibrils to restore softness (effective for 5-7 year old sheets)

- Controlled bleaching: Hydrogen peroxide baths at 40°C revive yellowed fabrics

- Edge reinforcement: Hand-stitching with gusset threads prevents hem unraveling

Master textile conservator insight: The Yale University Art Museum’s textile department recommends rotating between three identical sheet sets with quarterly professional laundering to achieve 15+ year lifespans from premium Egyptian cotton.

Risk mitigation matrix:

| Risk Factor | Early Signs | Corrective Action |

|---|---|---|

| Fiber breakdown | Increased pilling, lint production | Reduce wash temperature to 30°C, switch to front-loader |

| Dye migration | Color transfer to white towels | Use color-catcher sheets, wash with similar hues |

Implementing these professional quality assurance practices can extend bedding life by 3-5 years while maintaining like-new comfort. Document care routines and performance metrics to identify optimal maintenance schedules for your specific fabric blend and sleep environment.

Conclusion: The Art and Science of Quality Cotton Bedding

From field to fabric, we’ve explored how premium cotton transforms into luxurious bedding through meticulous harvesting, spinning, weaving, and finishing processes. The journey reveals that true quality lies in the details – long-staple fibers, proper weaving techniques, and responsible manufacturing all contribute to sheets that improve with age.

Whether you prioritize breathability (percale), silky softness (sateen), or sustainability (organic), understanding these processes empowers you to make informed choices.

Your next step: Audit your current bedding against the quality markers we’ve discussed – fiber length, weave type, and certifications. When replacing sheets, invest in the best cotton you can afford, knowing proper care will deliver years of comfort. Remember, exceptional sleep begins with consciously crafted textiles.

Frequently Asked Questions About Cotton Bedding Fabrics

What’s the difference between Egyptian and Pima cotton?

Both are extra-long staple cottons (1.4″+ fibers), but Egyptian cotton grows along the Nile River’s unique climate, producing slightly finer, silkier fibers. Pima cotton (grown in the US, Australia, and Peru) has exceptional strength and color retention.

For bedding, Egyptian cotton typically offers more luxurious drape, while Pima provides better durability – the Boll & Branch Signature Hemmed Sheets use Supima® cotton for this balanced performance.

How often should I replace my cotton sheets?

Quality cotton sheets last 3-5 years with proper care. Signs for replacement include thinning fabric (hold up to light – if you see through it easily), persistent odors after washing, or visible pilling across 30%+ of the surface.

Rotating between 3 sets and following our care guidelines can extend lifespan to 7+ years for premium options like Parachute’s Egyptian Cotton.

Why do my new cotton sheets feel stiff?

This is normal for untreated percale weaves. The stiffness comes from natural cotton fibers and the tight weave structure. It typically takes 3-5 washes (with warm water and mild detergent) to achieve optimal softness.

For faster softening, add 1/2 cup white vinegar to the rinse cycle – the acetic acid gently breaks down surface fibers without damaging them.

Is thread count really the most important quality factor?

No – this is a common misconception. While thread count matters, fiber quality and weave type are more significant. A 300-thread-count percale made from long-staple cotton (like Brooklinen’s Luxe Core) outperforms 800-thread-count short-staple sheets. Manufacturers can artificially inflate thread count by using multi-ply yarns, which reduce breathability without improving quality.

How can I prevent pilling on my cotton sheets?

Pilling results from fiber breakage. Prevent it by:

1) Washing in cold water (30°C max)

2) Using liquid detergent (powders are abrasive)

3) Avoiding fabric softeners (they coat fibers)

4) Line drying or tumble drying on low. For existing pills, use a fabric shaver – never pull them off, as this damages more fibers.

What’s better for hot sleepers – percale or sateen?

Percale’s 1-over-1-under weave promotes 25% more airflow than sateen, making it ideal for temperature regulation. The crisp hand feel also lies cooler against skin.

However, high-quality sateen (like Saatva’s 300-thread-count organic sateen) with moisture-wicking treatments can work well if you prefer a silkier texture.

Are organic cotton sheets worth the higher price?

Yes, for three reasons:

1) No pesticide residues (important for sensitive skin)

2) Typically uses longer, stronger fibers

3) More sustainable production. GOTS-certified organic cotton (like Coyuchi uses) ensures integrity from farm to finished product. The price premium (20-30%) pays off in longevity and peace of mind.

How do I remove yellow stains from white cotton sheets?

For body oil stains:

1) Pre-treat with baking soda paste (3:1 water to soda)

2) Wash with oxygen bleach (not chlorine) at 40°C

3) Sun-dry – UV rays naturally bleach cotton.

For stubborn stains, soak overnight in enzymatic detergent. Always check care labels first, as some treatments (like antimicrobial coatings) require special care.