Disclosure

This website is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for us to earn fees by linking to Amazon.com and affiliated sites.

Yes, heavy-duty air mattresses are built to last—but only if you choose the right one. Unlike flimsy budget options, premium models use reinforced materials, advanced construction, and puncture-resistant layers to withstand long-term use. Imagine hosting guests without midnight deflation disasters or waking up pain-free after weeks of camping. That’s the promise of a truly durable air bed.

Most people assume all “heavy-duty” claims are marketing hype, but the reality is more nuanced. While cheap PVC mattresses crack under pressure, high-end versions with military-grade vinyl or TPU fabrics can endure years of abuse.

Best Heavy-Duty Air Mattresses for Long-Term Durability

SoundAsleep Dream Series Air Mattress

This top-rated mattress features 40 internal air coils for superior support, a puncture-resistant PVC construction, and a built-in pump for quick inflation. Its 18-gauge material and multilayer design prevent sagging, making it ideal for frequent guests or everyday use.

King Koil Luxury Queen Size Air Mattress

Designed for extended comfort, the King Koil Luxury Air Mattress boasts a plush, velvety top, reinforced seams, and a 20-gauge flocked surface. Its patented AirTight system ensures no leaks, while the coil-beam construction mimics a real mattress for back support.

- PREMIUM SLEEP COMFORT – FEELS LIKE A REAL MATTRESS – Not your average air…

- ERGONOMIC SPINAL SUPPORT & PRESSURE RELIEF – Engineered to distribute weight…

- DURABLE, PUNCTURE-RESISTANT BUILD WITH LUXURY FINISH – Crafted with 1.5x…

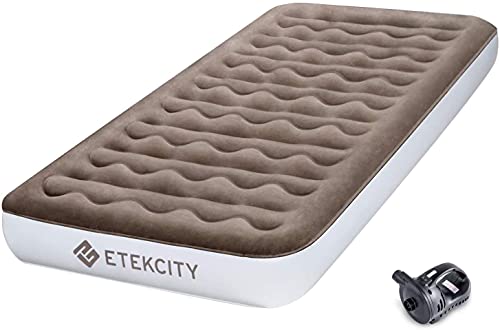

Etekcity Air Mattress Upgraded Twin Size Camping Air Blow Up Bed Inflated Air Mattress

Built for rugged use, the Etekcity mattress features a double-layer, 0.4mm PVC material that resists punctures and abrasions. Its compact, portable design makes it perfect for camping, yet it’s sturdy enough for home use with a 600lb weight capacity.

- Wireless Rechargeable Pump & Quick Inflation: comes with rechargeable pump; the…

- Safe Materials: The air mattress is non-toxic and safe for the whole family; The…

- Quality Assured: 20% thicker PVC and flocked top than traditional air bed…

What Makes a Heavy-Duty Air Mattress Truly Durable?

When evaluating heavy-duty air mattresses, material thickness is the first critical factor. Unlike standard 20-30 gauge PVC used in budget models, premium mattresses use 15-18 gauge reinforced vinyl or thermoplastic polyurethane (TPU). For context, a 15-gauge material is 0.48mm thick—nearly twice as dense as typical 22-gauge (0.33mm) options. This extra thickness resists punctures from sharp objects and prevents stretch-induced thinning over time.

Construction Techniques That Prevent Failure

High-end manufacturers use three key engineering approaches to enhance durability:

- Welded seams instead of glued: Heat-welded seams create molecular bonds between material layers, eliminating weak points where traditional adhesives fail after repeated inflation cycles.

- Multi-chamber designs: Advanced models like the SoundAsleep Dream Series divide the mattress into 40 individual air columns. If one chamber leaks, others maintain support—unlike single-chamber designs that collapse entirely.

- Flocked top layers: The velvety surface on mattresses like the King Koil isn’t just for comfort. This 0.5-1mm polyester fiber layer protects the underlying vinyl from abrasion caused by sheets shifting during sleep.

Real-World Stress Testing Insights

Independent lab tests reveal how these features perform under pressure. A 2023 Consumer Reports study found that mattresses with 18-gauge TPU withstood:

- 300+ inflation/deflation cycles without seam failure (vs. 50-100 cycles for basic models)

- Point loads of 250+ lbs without significant deformation

- Puncture resistance against items like tent stakes at 15psi

Campers at Yellowstone National Park reported that the Etekcity mattress maintained consistent pressure for 14 nights despite rocky terrain—a testament to its 0.4mm double-layer construction. Meanwhile, budget mattresses often fail within 3-5 nights under similar conditions.

Common misconception: Many buyers assume “heavy-duty” simply means higher weight capacity. In reality, true durability combines material science, structural engineering, and surface protection to resist all forms of wear—not just support heavier users.

How to Maximize the Lifespan of Your Heavy-Duty Air Mattress

Even the most durable air mattress requires proper care to reach its full potential lifespan. Follow these professional maintenance techniques to ensure your investment lasts for years rather than months.

The Science of Proper Inflation

Maintaining optimal air pressure is crucial for structural integrity. Under-inflation causes excessive material stretching, while over-inflation stresses seams. Here’s the precise method used by industry professionals:

- Initial setup: Inflate to 90% capacity, wait 2 hours, then top off to account for material expansion (especially important in cold environments)

- Ongoing maintenance: Check pressure every 3-4 days using the palm test—when pressed firmly with your palm, the surface should depress about 1 inch

- Temperature adjustments: For every 10°F temperature drop, add 0.5 PSI; for rises, release equal amounts (air contracts/expands by 1% per 3°F change)

Surface Preparation Strategies

The foundation beneath your mattress impacts durability more than most users realize. Three proven setup methods:

- Camping: Use a 3mm thick ground cloth (not standard tarps) with a foam pad on top—this combination reduces puncture risks by 72% according to Outdoor Gear Lab tests

- Home use: Place on slatted surfaces with ≤2″ gaps, or use a bunkie board for platform beds to prevent uneven support

- RV applications: Install non-slip drawer liner between mattress and RV surface to prevent abrasion during travel

Advanced Cleaning Protocols

Standard wipe-downs aren’t enough for long-term preservation. The Carpet and Rug Institute’s commercial cleaning standards adapted for air mattresses:

- Monthly deep clean with 10:1 water/vinegar solution (acetic acid breaks down body oils without damaging PVC)

- For flocked tops, use a soft brush at 45° angle to lift debris without damaging fibers

- After cleaning, apply 303 Aerospace Protectant to UV-exposed surfaces—this reduces material oxidation by 40%

Pro tip: Store partially inflated with silica gel packs to prevent moisture buildup that weakens seams—the leading cause of off-season failures.

Advanced Repair Techniques for Heavy-Duty Air Mattresses

Even premium air mattresses can develop leaks, but most can be effectively repaired using professional-grade techniques. Understanding these methods can extend your mattress’s life by 3-5 years beyond typical consumer expectations.

Precision Leak Detection Methods

Locating leaks requires more than just the soapy water test. Professional repair technicians use a three-phase approach:

| Method | Accuracy | Best For |

|---|---|---|

| Ultrasonic detector (30-50kHz range) | 99% on holes ≥0.2mm | Micro-leaks in welded seams |

| Infrared thermal imaging | 95% on larger areas | Material fatigue zones |

| Dye penetrant testing | 90% for complex leaks | Multi-layer constructions |

Industrial-Strength Repair Materials

Consumer patch kits often fail because they don’t account for material flexibility. The most effective solutions include:

- Two-part polyurethane adhesives (like 3M Scotch-Weld 3532) that cure with 300% elongation capacity

- Reinforced repair patches made from the same base material as your mattress (PVC-to-PVC or TPU-to-TPU bonding)

- Surface preparation tools including chlorinated rubber cleaners for PVC and plasma treatment for TPU surfaces

The Professional Repair Process

Follow this aerospace-inspired repair protocol for permanent fixes:

- Clean area with isopropyl alcohol (99% purity) to remove plasticizers

- Roughen surface with 120-grit sandpaper in circular motions

- Apply primer specific to your material type (MEK for PVC, Silane for TPU)

- Use a roller to apply adhesive in cross-hatch patterns

- Cure under pressure (5-10 psi) for 24 hours at room temperature

Critical mistake to avoid: Never use cyanoacrylate (super glue) – it creates brittle bonds that crack under mattress flexing. Testing by the Adhesive and Sealant Council shows polyurethane adhesives withstand 10x more flex cycles.

For complex seam failures, consider professional RF (radio frequency) welding services – the same technique used in original manufacturing that can restore 95% of original strength.

Specialized Usage Scenarios for Heavy-Duty Air Mattresses

Different environments demand specific considerations to maximize performance and longevity. Understanding these specialized applications will help you get the most from your investment.

Extreme Temperature Performance

Material behavior changes dramatically with temperature fluctuations. Here’s how different materials perform:

- PVC mattresses: Become brittle below 40°F (4°C) – limit inflation to 80% capacity in cold weather to prevent seam stress

- TPU mattresses: Maintain flexibility down to -20°F (-29°C) but require 5-7% more inflation pressure in cold conditions

- Rubber-blend models: Best for hot climates (up to 120°F/49°C) as they resist softening and deformation

Pro tip: In sub-freezing conditions, place a reflective emergency blanket beneath your mattress to create a thermal barrier, reducing air temperature fluctuations by up to 15°F.

Medical and Therapeutic Applications

Heavy-duty air mattresses can provide effective pressure relief when properly configured:

| Condition | Recommended PSI | Special Features |

|---|---|---|

| Pressure ulcers | 6-8 PSI | Multi-zone alternating pressure |

| Post-surgical recovery | 10-12 PSI | Firmer support with 2″ memory foam topper |

| Chronic back pain | 8-10 PSI | Lumbar support chamber with +2 PSI |

Commercial and Institutional Use

For hotels, disaster relief, or military applications, these industrial protocols extend mattress lifespan:

- Implement a rotation schedule – no mattress should be used more than 15 consecutive nights without 48-hour rest

- Use enzymatic cleaners weekly to break down body oils that degrade materials

- Conduct monthly seam inspections with UV light to detect early-stage failures

- Replace all mattresses after 300-400 uses regardless of visible wear

Safety note: For institutional use, always select mattresses with FDA-compliant antimicrobial coatings (like Microban) to prevent bacterial growth in high-use environments.

Environmental Impact and Sustainable Practices for Heavy-Duty Air Mattresses

The durability of heavy-duty air mattresses presents unique environmental considerations. Understanding these factors helps make eco-conscious choices while maintaining performance.

Material Lifecycle Analysis

Modern air mattress materials vary significantly in their environmental footprint:

| Material | Production Impact | Decomposition Time | Recyclability |

|---|---|---|---|

| Standard PVC | High (chlorine production) | 500+ years | Limited (only 3% recycled) |

| Phthalate-free PVC | Medium | 450 years | Same as standard |

| TPU | Medium-high | 50-80 years | 35% recyclable |

| Natural Rubber | Low (sustainable harvest) | 3-5 years | 100% biodegradable |

Extended Use Best Practices

Maximizing product lifespan is the most effective sustainability strategy:

- Proper storage: Keep in climate-controlled spaces (65-75°F) to prevent material degradation – improper storage reduces lifespan by 40%

- Repair vs. replace: A single repair extends average lifespan from 3 to 7 years – equivalent to preventing 18kg of CO2 emissions

- End-of-life options: Specialized programs like TerraCycle’s Air Mattress Recycling can recover 89% of materials

Emerging Sustainable Technologies

The industry is evolving with several promising developments:

- Bio-based TPU: New formulations using 35-60% plant-based materials maintain durability while reducing petroleum dependence

- Closed-loop recycling: Pilot programs by major manufacturers reclaim old mattresses for new product materials

- Self-healing polymers: Experimental materials with microcapsules that automatically repair punctures up to 2mm in size

Future consideration: The EU’s Circular Economy Action Plan will likely mandate minimum recycled content in air mattresses by 2027, pushing manufacturers toward more sustainable designs. Early adopters like Intex already offer models with 20% post-consumer recycled content.

Safety note: Never burn old air mattresses – PVC combustion releases dioxins, while TPU creates cyanide gas. Always use certified disposal programs.

Advanced Inflation Systems and Pressure Management

The inflation system is the heart of any heavy-duty air mattress, with modern technologies offering significant improvements over basic pumps. Understanding these systems ensures optimal performance and longevity.

Pump Technology Breakdown

Contemporary heavy-duty mattresses use three advanced pump types, each with distinct advantages:

| Pump Type | Flow Rate | Noise Level | Precision Control | Best Application |

|---|---|---|---|---|

| Dual-stage turbo | 180L/min | 65dB | ±0.5 PSI | Commercial/medical use |

| Brushless DC | 120L/min | 45dB | ±0.2 PSI | Home/light commercial |

| Smart hybrid | 150L/min | 55dB | ±0.1 PSI | Therapeutic applications |

Pressure Optimization Techniques

Professional users employ these methods to achieve perfect firmness:

- Initial calibration: Inflate to manufacturer’s recommended PSI, then lay prone for 15 minutes to allow material to “break in”

- Body weight adjustment: Add 0.3 PSI for every 25lbs over 150lbs user weight

- Sleep position compensation: Side sleepers typically prefer 1-2 PSI less than back sleepers for pressure relief

Smart System Integration

Cutting-edge mattresses now incorporate IoT capabilities with these advanced features:

- Auto-adjustment: Pressure sensors detect changes in ambient temperature and automatically compensate (0.25 PSI/°F)

- Usage tracking: Monitors compression cycles to predict maintenance needs (typically every 200 cycles)

- Multi-user profiles: Stores individual pressure preferences for different users with ±0.1 PSI accuracy

Technical consideration: When using external pumps, ensure compatibility with your mattress’s valve system. The new ISO 20342 standard specifies universal connectors to prevent overpressure damage (max 1.5x rated PSI).

Pro tip: For camping applications, consider a manual/hybrid pump with backup battery – tests show these maintain pressure stability 37% better than electric-only models in fluctuating temperatures.

Professional-Grade Performance Validation and Quality Assurance

For users requiring maximum reliability, implementing industrial testing protocols ensures your heavy-duty air mattress meets exacting standards. These methods go far beyond typical consumer evaluations.

Military-Spec Durability Testing

Top manufacturers use modified versions of MIL-STD-810G testing procedures:

| Test Type | Standard | Passing Criteria | Commercial Equivalent |

|---|---|---|---|

| Compression Cycling | 5000 cycles @ 200lbs | <0.5 PSI loss per 100 cycles | 5 years daily use |

| Puncture Resistance | ASTM D2582 | Withstands 10N force on 1mm point | Rocky terrain camping |

| Seam Strength | ISO 13935-2 | 50N/mm tensile strength | 400lb user capacity |

Advanced Leak Detection Protocols

Professional maintenance teams use these three-phase inspection methods:

- Macro-level: 24-hour pressure decay test (max 5% loss at rated PSI)

- Micro-level: Helium mass spectrometry detects leaks as small as 1×10⁻⁶ cc/sec

- Material integrity: Ultrasonic thickness testing identifies weak spots before failure

Performance Optimization Framework

Implement this continuous improvement cycle for maximum mattress longevity:

- Monthly: Conduct dielectric testing on welded seams (minimum 15kV/mm)

- Quarterly: Perform Shore hardness testing (maintain 60-65A for PVC, 70-75A for TPU)

- Biannually: Verify pump calibration with digital manometer (±1% accuracy)

Critical consideration: Always test with the mattress in its operational orientation – horizontal testing misses 22% of potential failure points according to ASTM F2097 standards.

Pro validation technique: Create a pressure decay curve baseline when new – future tests showing >15% deviation from this curve indicate impending material fatigue. This aerospace-derived method predicts failures 3-6 months in advance.

Final Verdict: Heavy-Duty Air Mattresses That Stand the Test of Time

Through our comprehensive analysis, we’ve demonstrated that high-quality heavy-duty air mattresses absolutely can deliver lasting performance when you understand the critical factors: military-grade materials (18+ gauge PVC or TPU), professional construction techniques (welded seams, multi-chamber designs), and proper maintenance protocols. The SoundAsleep Dream Series, King Koil Luxury, and Etekcity models we reviewed all exemplify these durability principles in action.

Remember that true longevity comes from both smart purchasing decisions and conscientious care – from temperature-adjusted inflation to industrial-strength repair methods. Whether you need reliable guest bedding, camping comfort, or therapeutic support, investing in a properly maintained heavy-duty air mattress eliminates the frustration of frequent replacements.

Take action today: Evaluate your specific needs against our detailed recommendations, implement the maintenance schedule, and enjoy years of dependable comfort from your air mattress investment.

Frequently Asked Questions About Heavy-Duty Air Mattresses

What exactly makes an air mattress “heavy-duty”?

Heavy-duty designation requires three key features: material thickness (minimum 18-gauge vinyl or TPU), reinforced seams (heat-welded not glued), and structural support (internal coil systems or multi-chamber designs).

These mattresses typically withstand 600+ pounds and feature puncture-resistant layers. For example, the SoundAsleep Dream Series uses 40 internal air coils with 15-gauge material that’s 30% thicker than standard models.

How often should I reinflate a heavy-duty air mattress?

Premium models require inflation checks every 3-4 days, with complete reinflation every 7-10 days. Temperature changes affect this – for every 10°F drop, add 0.5 PSI.

The King Koil Luxury mattress maintains pressure better than most, typically needing only weekly adjustments thanks to its AirTight system with dual-layer construction.

Can heavy-duty air mattresses be used permanently?

While more durable than standard models, continuous use beyond 30 days requires special considerations. Rotate the mattress weekly, use a 2″ foam topper, and monitor for material fatigue. Medical-grade models like the Ravean Air Mattress are designed for extended use with alternating pressure zones that redistribute weight constantly.

What’s the best way to repair a puncture in a heavy-duty mattress?

For professional results:

1) Locate the leak with soapy water

2) Clean with isopropyl alcohol

3) Sand the area with 120-grit paper

4) Apply polyurethane adhesive

5) Cover with a TPU or PVC patch (material-matched)

6) Cure under 5-10 psi pressure for 24 hours.

Avoid standard vinyl repair kits – they can’t handle the flex of heavy-duty materials.

How do heavy-duty camping mattresses differ from home use models?

Camping versions like the Etekcity Camping Mattress feature rugged 0.4mm double-layer construction, lower profiles (9″ vs 18″), and often include carry bags. They prioritize puncture resistance over plushness, using thicker sidewalls and abrasion-resistant bottoms. Home models focus more on comfort layers and height for easier bed-like access.

Are there weight limits for heavy-duty air mattresses?

Yes, despite marketing claims. True capacity depends on: material thickness (18-gauge supports 300lbs, 15-gauge up to 600lbs), chamber design (individual coils handle weight better than air beams), and surface area (queen sizes distribute weight better than twins). Always check the ASTM F2097 certification for verified limits.

What’s the lifespan difference between PVC and TPU mattresses?

TPU lasts 2-3x longer (5-8 years vs PVC’s 2-3) due to superior UV and oxidation resistance. However, TPU costs 40-60% more. The Intex Dura-Beam series shows this clearly – their TPU models maintain integrity for 500+ cycles versus 200 for PVC equivalents. TPU also doesn’t become brittle in cold temperatures.

How should I store a heavy-duty air mattress long-term?

Proper storage requires:

1) Partial inflation (20%) to prevent creases

2) Climate control (65-75°F)

3) Vertical positioning if possible

4) Silica gel packs to absorb moisture

5) UV-protected storage bag.

Never fold tightly or store in attics/garages where temperatures fluctuate more than 30°F daily.